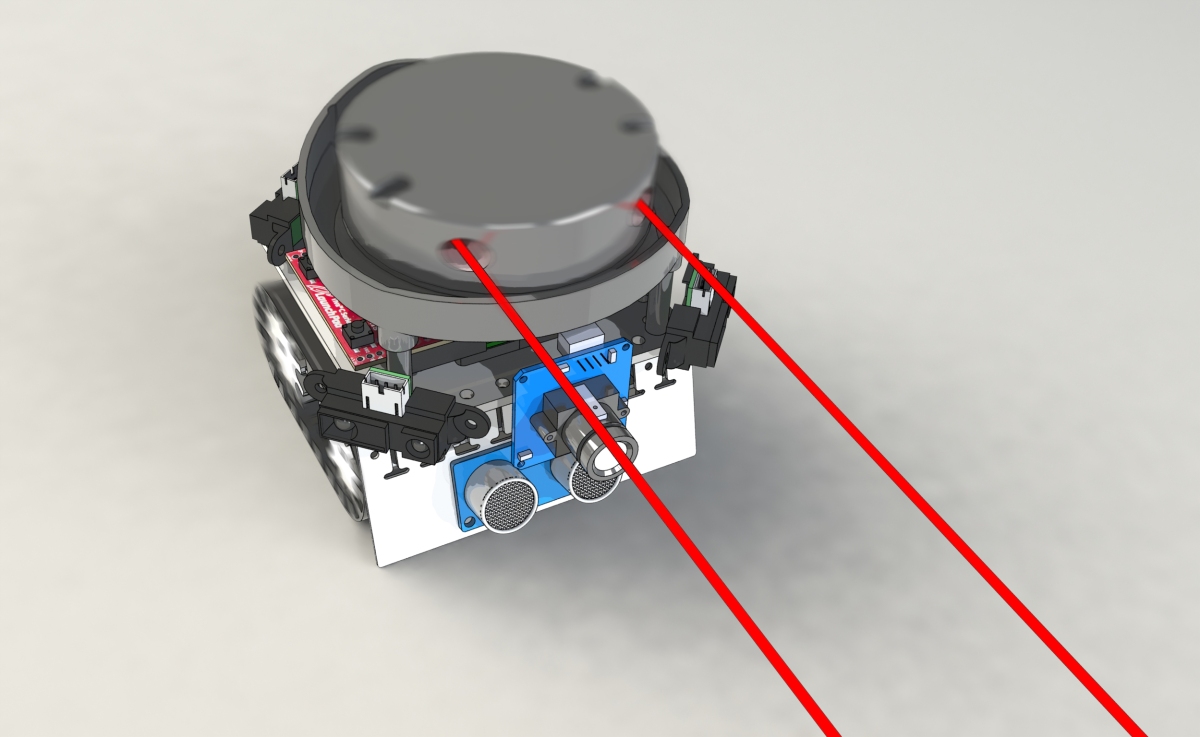

I’ve been working on a robot to study the SLAM (Simultaneous Localization And Mapping) algorithm so I’ll post what’ve done so far in this article.This project pretty much involved all the stuff I know and all the knowledge I used in other projects.So for the time being I’ll just put the link of these previous projects for some of my thought and save some time.

Month: February 2016

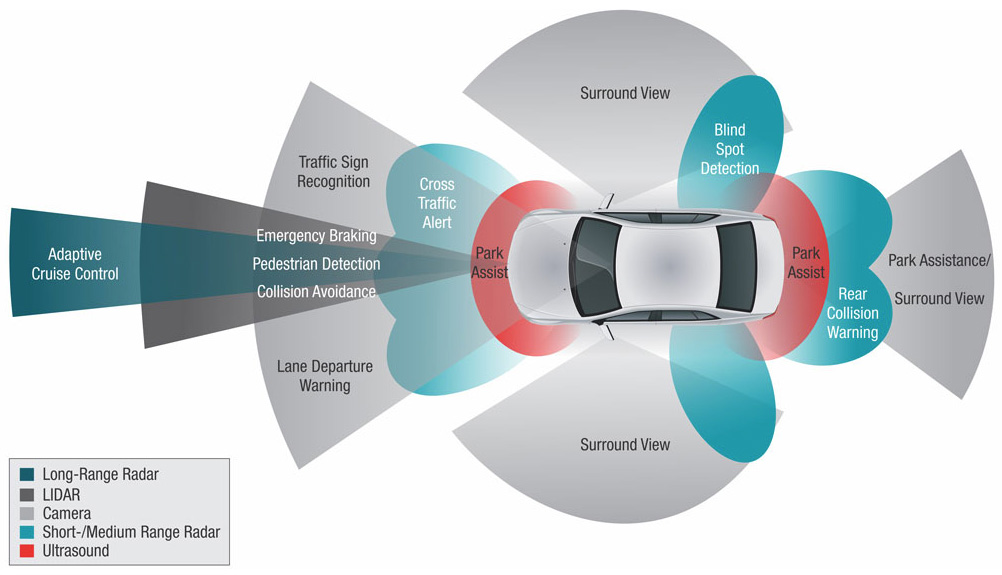

A Review of Multisensor Data Fusion for ADAS

This is a review of Mahdi’s research of ‘Multisensor Data Fusion Strategies for Advanced Driver Assistance Systems’[1].This paper introduced the current(2009) research result of ADAS on vehicles.The authors then proposed a 4-layer model for multisensor fusion,at last,they proposed using fuzzy logic for multisensor fusion in Automatic Cruise Control(ACC).This is also one of my preliminary research on ADAS.Later on I’ll post the SLAM robot I built for simulating the self-driving vehicle control,as well as practicing the algorithms in Artificial Intelligent for Robotics course on Udacity.

Continue reading “A Review of Multisensor Data Fusion for ADAS”

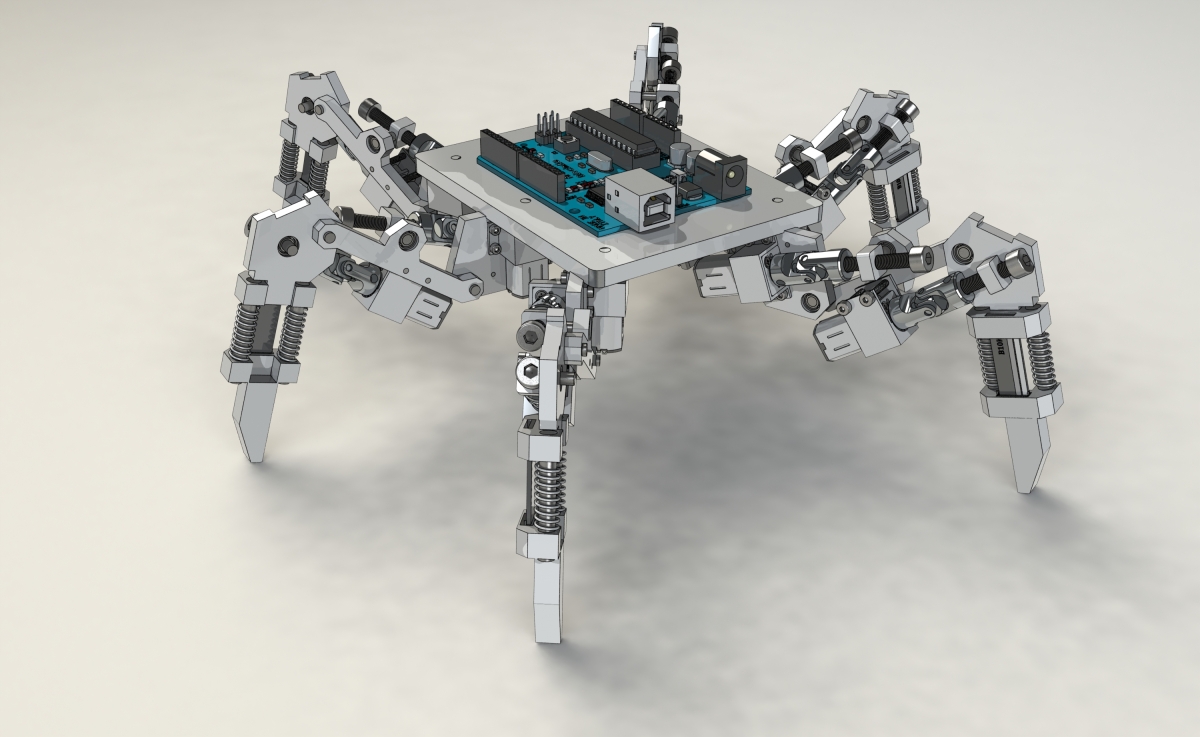

Screw Driven Hexapod Robot Design

This is a robot I designed in summer holiday in 2012.This design is mainly a Solidworks modeling practice.I tried to use CAD software and simulation to verify my idea instead of trial and error with the gears,which was what I used to do.I did some analysis on the leg structure by hand at first,but it turned out to be very complicated.So later on I turned to use Solidworks to simulate the legs.The project was abandon later on because I had to put my effort in my CNC project,which lasted for more than two years.But I decided to post it out and maybe someone is interested in such a screw driven mechanism and my work could make some small contribution.

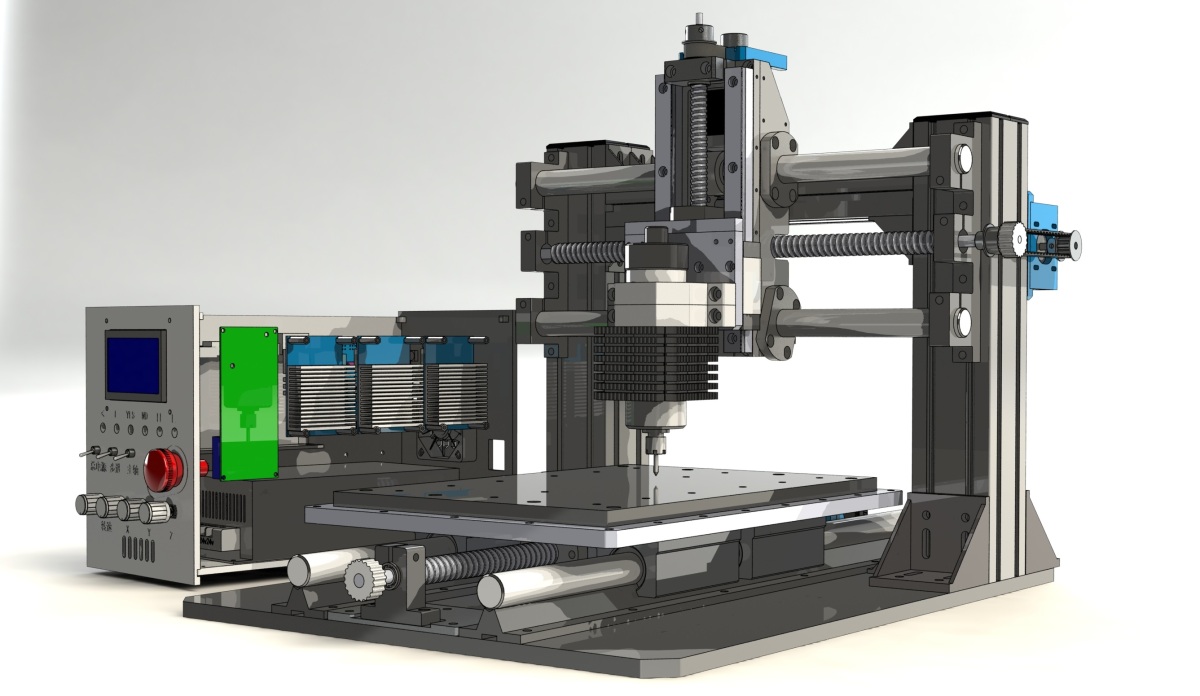

CNC Machine II

This post records my favorite CNC machine I’ve ever built.It’s actually the third machine I built and it’s an improvement of the previous one.Since I’ve already had a machine before building this one so I have the ability to make more complicated parts which I wasn’t able to make before.My goal is to make a compact desktop CNC milling machine so that I can implement my electronics or mechanical projects easily.Before having a CNC machine,I had been soldering PCB using those prototyping board for almost two years.It usually took me several nights to solder a control board for my RC car and then took several more nights to debug the board.If the board has a severe problem,or I want to make some improvement,then I had to start over again and a week is gone.Such a bummer.After having a machine everything becomes so simple.I started to use EDA software to design a PCB and verify my idea.Some times I got a good idea then I can implement it and test it within a day.I also use Solidworks to work with Altium Designer because most of my projects are mechatronics ones.Importing the board into Solidworks and checking if it fits in the case or robot makes design so easy and quick. Continue reading “CNC Machine II”